What is CLARUS®?

Synthetic fabrics are drowning the planet in textile waste and driving climate change. Natural Fiber Welding imbues natural fibers like cotton with the versatility of synthetics. This revolutionary technology is our opportunity to replace synthetic fabrics across the global fashion supply chain. It’s the beginning of a new era for the material economy.

Once upon a time, swimsuits were made from wool or cotton canvas. Raingear was made from seal intestines, rubber, or waxed cotton. With those options, you’d think twice before taking a dip or a walk in the rain.

But in the mid-20th century, manufacturers began engineering clothing from crude oil-derived plastics. Plastic fibers like polyester — finer, longer, and stronger than natural fibers like cotton — could be knit or woven into synthetic fabrics, with never-before-possible performance qualities.

Polyester vs natural fibers

“Moisture-wicking,” “quick-drying,” “ultra-lightweight," polyester and its ubiquitous cousins (nylon, elastane, vinyl) set the standards we now expect from our high-performance clothing. Despite obvious downsides — they generally don’t feel as nice on the skin and start to smell a lot faster than their natural counterparts — synthetics have radically reshaped the global textile supply chain. Today, synthetics account for roughly two-thirds of global fiber production and the majority of that is polyester.

Cotton, once dominant, simply hasn’t been able to compete. None of the natural materials — including hemp, linen, and wool — could be manipulated to make possible sweat-wicking, mechanical stretch, abrasion resistance, or quick-drying properties. Natural fibers could not be formed and shaped the same way synthetics could. Because of this, it was considered impossible to make natural fabrics with the performance versatility of synthetics.

That is, until CLARUS®.

What is CLARUS?

Dr. Luke Haverhals, NFW’s CEO, discovered that natural fibers can be molded and shaped to take on the performance qualities of synthetics by using ionic liquids (i.e., liquid salts). Several families of ionic liquids are well-known to dissolve cellulose, an abundant organic compound present in the cell walls of natural materials. The patented CLARUS technology platform uses ionic liquids to swell, mobilize and then reconstruct cellulosic bonds at the molecular level (e.g., different methods of “welding” fibers). When carefully engineered and controlled, this creates stronger, more durable, and functional yarns and fabrics. The salt is removed and recaptured for reuse, leaving nothing but the original natural fiber behind. The end product is 100 percent natural fiber, nothing more, nothing less—but with new performance characteristics.

Natural yarns made with this patented process, sometimes called fiber welding, exhibit the best qualities of both natural fibers and synthetics. Further, different CLARUS technologies can give ultra-short recycled fibers a new life. This discovery is the most significant innovation in natural fibers in many decades. Natural Fiber Welding, founded by Dr. Haverhals in 2015, has pioneered CLARUS, a breakthrough textile platform technology, to create the new shape of cotton and natural fibers. NFW is engineering and scaling this technology to give a wide variety of properties never before seen in natural materials by knitting and weaving innovative new natural textiles.

“This is the most exciting innovation in textiles that I have seen in my 40-plus-year career in the textile industry,” Jimmie Grow, a cotton industry expert, told Textile World.

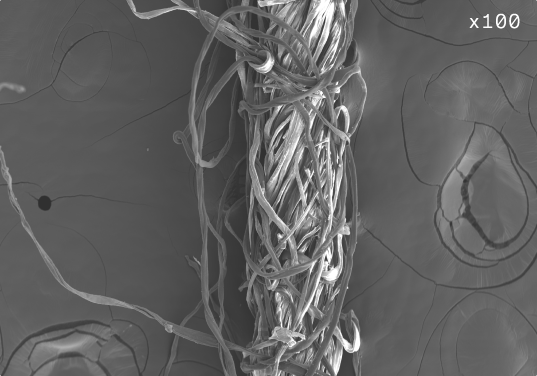

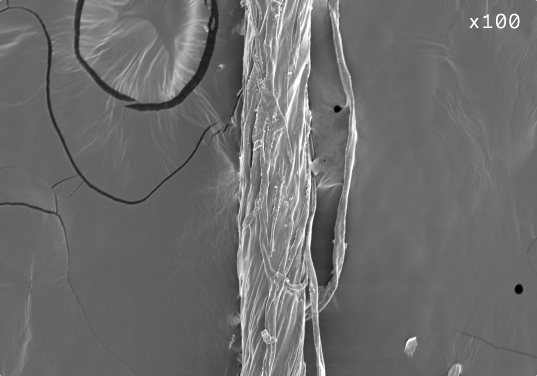

Microscopic image of cotton yarn lengthwise before (left) and after (right) one type of fiber welding transformation.

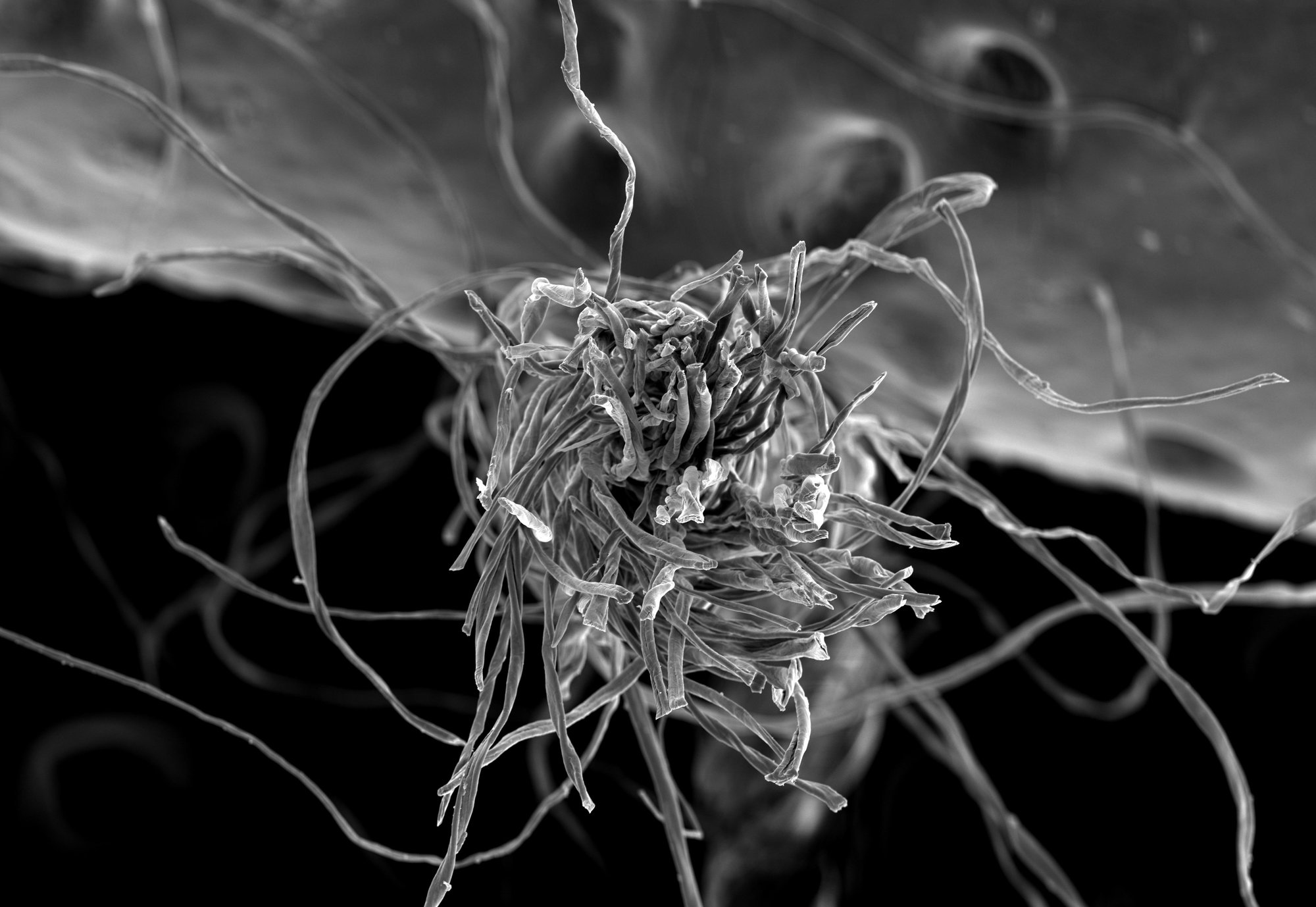

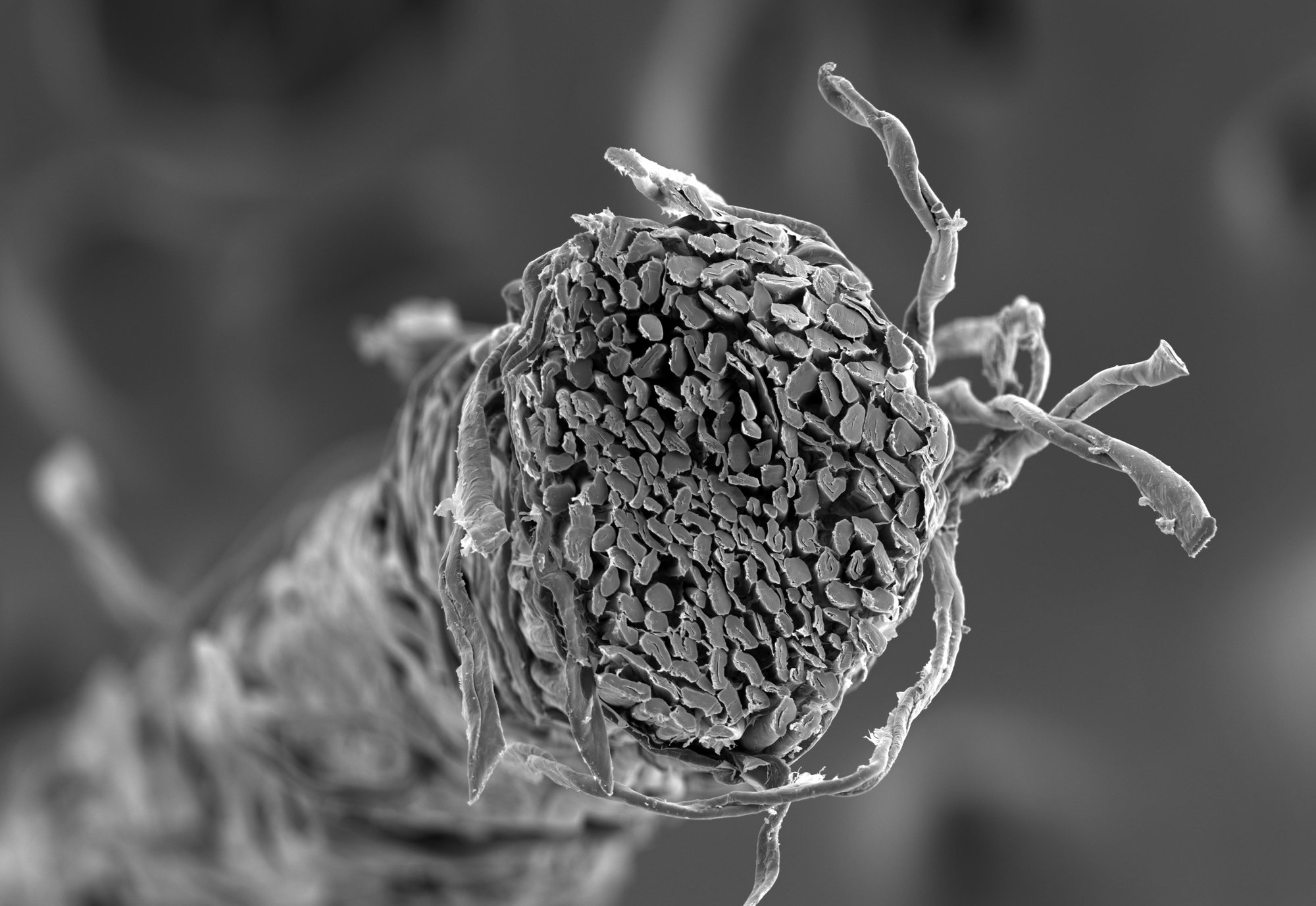

Microscopic image of cotton yarn cross-section before (left) and after (right) another type of fiber welding transformation.

Depending on a brand’s needs, NFW adjusts patented processes to meet a wide range of different use-cases and ultimate properties. CLARUS technologies can imbue natural fibers with enhanced strength, durability, and abrasion-resistance; faster moisture-wicking and preferential moisture management; breathability; and even the ability to use cotton in warp knits (typically only possible for synthetic yarns). The tunability of the process creates opportunities for customization not previously possible with cotton and other natural fibers like hemp.

At the same time, the processed textiles maintain the natural integrity of the natural fibers, so that the yarns and fabrics retain the core properties we love: all-day comfort, water absorption, and natural odor resistance. Additionally, any natural fibers that shed from products made using CLARUS technology are all-natural, just like the fabric itself, and do not pose health risks like those associated with microplastics. It is well known that natural “microfibers” (which because they are natural are really “micro-nutrients”) of cellulose degrade and are fully biocompatible with their environments. Seaweed, driftwood, etc., are other examples of cellulosic materials that also break down into cellulosic nutrients.

From a sustainability and performance standpoint, CLARUS technologies are a complete paradigm shift.

Environmental impact of polyester

Despite their usefulness, polyester and its synthetic cousins have only ever been bad news for the environment and humans.

These fabrics are made from plastic, which is derived from crude oil and manufactured by burning vast quantities of natural gas. Presently, the relatively low cost of polyester garments doesn’t factor in the astronomical environmental toll of the fossil fuel industry at all stages in the supply chain. Drilling, fracking, oil spills, methane leaks, and dumping have destroyed countless ecosystems and communities. Presently, little to none of these impacts are factored into the footprint of plastic textiles by many brands and sustainability indices.

The public health impacts of plastics are also not considered. One of the emergent issues caused by the recent explosion of synthetic fabrics in the textiles industry is microplastic pollution. We now know that synthetic garments shed fibrous microplastics (fibers less than 5 mm) when worn, washed, and dried. As a result, we are all breathing, eating, and drinking plastic. A new study suggests microplastics can even latch onto the outer membranes of human red blood cells and stretch them out such that it may affect their ability to transport oxygen. There are threats to animal welfare as well. For example, even hermit crabs are negatively impacted by exposure to microplastic pollution.

Within the textile industry, which according to one study is responsible for 35 percent of plastic microplastic pollution, there is very little acknowledgement of the microfiber issue, in particular, what to do about it.

Scientists at DuPont and Imperial Chemical Industries invented polyester in the middle of the twentieth century, and the chemical companies sprang into production. Now, as the energy sector’s demand for fossil fuels begins to level off, the fossil fuel industry is pushing plastics (like polyester) to drive continued growth and profit.

Polyester production itself is a messy business. Isolating the ingredients for polyester from crude oil requires an energy-intensive refinement process, which produces pollutants including carbon monoxide, sulfur dioxide, nitrogen oxides, benzene, toluene, ethylbenzene, xylene, and particulate matter. Turning those ingredients into polyester creates wastewater tainted with chemical residues.

According to the Ellen MacArthur Foundation, as of 2015 more than 100 billion articles of clothing are manufactured every year. The vast majority are made with synthetic fibers. Like the raw materials from which they are made, synthetic garments themselves are non-renewable. Throughout its life cycle, polyester leaches microplastics into our drinking water, soil, air, and oceans. Seventy-three percent of clothing material is ultimately thrown away. Only a trace amount of polyester clothing is recycled (and it can’t be recycled repeatedly because it degrades each time). Moreover, recycling plastics is now also known to only slightly reduce the large global carbon footprint of plastics since these recycling processes are also energy intensive.

What is worse is recycled polyester, seemingly a saving grace for continued use of polyester fibers in the fashion industry, actually sheds more microfibers pollution than its virgin counterparts. Eventually, polyester is burned (releasing greenhouse gases) or dumped into a landfill or the ocean (where it sheds further microplastics). Continuing on this path is clearly not sustainable nor sufficiently circular to be considered as a long term, global solution.

Sustainability advantages of CLARUS

CLARUS technologies, by contrast, give brands the option to use natural materials, such as mechanically recycled cotton, to create high-performance fabrics. NFW can utilize natural materials that, until now, have been considered “waste” and seen limited adoption. When a natural material like cotton is mechanically recycled, the resulting recycled material has short fibers and thus makes for weak yarns and less durable fabrics. This severely decreases its value, making these recycled fibers more suitable for manufacturing building insulation than new garments. With CLARUS, recycled fabrics made from natural ‘waste’ are now suitable for high-performance apparel and is the comprehensively sustainable alternative to polyester.

Importantly, unlike polyester, natural fibers, like cotton, are plant polymers (cellulose) that biodegrade and provides nutrients back into the environment. If clothing made with CLARUS technology ends up in the ocean, cellulose will not pollute the environment with microplastics but instead degrades into nutrients.

The CLARUS technology platform allows natural materials to compete with synthetics in performance, while far surpassing them in sustainability.

Change at scale

CLARUS technologies are fiber agnostic. That is to say, NFW’s closed-loop, green chemistry processes can be applied to virtually any natural fiber: hemp, silk, wool, flax — theoretically, even fibers from thistles growing on the side of an interstate.

A key reason synthetics have become so central to our fashion supply chain is their ability to be molded and shaped to create performance qualities like moisture management and durability. . NFW opens up a world of new materials that can outcompete and replace synthetics by instead using photosynthesis. Because more new plant matter grows in an average day on Earth than the combined tonnage of plastics produced globally in more than a year, the approach of using abundant, redundant plant fibers can sustainably scale to everyone.

NFW can upcycle the natural fibers already in rotation (e.g., recycled cotton), and can also tap into the other incredible abundance of fibers that planet earth produces daily. With NFW technologies, such as CLARUS, materials that can be reused, recycled, regrown (ideally through a regenerative agricultural practice), returned safely to the earth, and can become the foundation of a truly sustainable and circular material economy. Doubling down on the status quo of finite fossil fuels with their extraordinary environmental and human cost is not an option for people today nor for our children.

Because CLARUS fiber welding technologies are not dependent on the source of cellulose, man-made cellulosic fibers (MMCFs) are also compatible. As great companies like Lenzing continue to develop their material offerings, CLARUS technologies are able to increase the efficiency of reuse and ultimate performance of these materials as well. Improved durability, abrasion resistance, reduced pilling and moisture management properties can all be imparted into MMCFs. NFW believes that unlocking nature’s potential means not only improving plant fibers the first time they are used, but enabling the best performance every time they are used and is a unique competitive advantage of the CLARUS platform.

CLARUS is not simply bringing new products to the market. It’s our mission to replace synthetic fabrics across the global fashion supply chain. NFW and platforms like CLARUS represent the beginning of a new era of a comprehensively sustainable (e.g., low carbon, circular, natural) materials economy.

Want to learn more about CLARUS and its potential applications in your business? Please, get in touch.